Quality

From product design to process control, at the heart of every Haliburton product is a quality system designed to achieve our Gold Standard food safety and quality objectives.

A commitment to integrity

From product design to process control, at the heart of every Haliburton product is a quality system designed to achieve our Gold Standard food safety and quality objectives.

Ask our customers, vendors and industry peers and they’ll tell you – Haliburton is renowned for their consistent, high-quality food products and the toughest food safety testing standard in the industry.

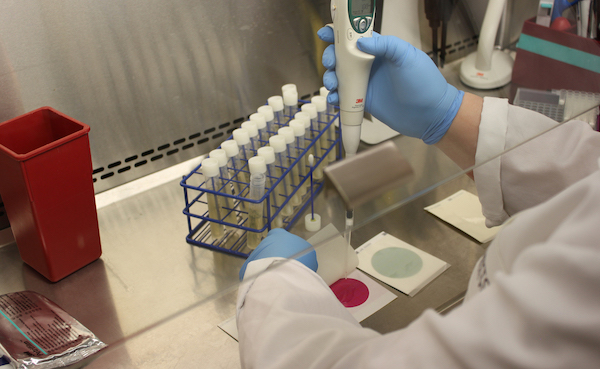

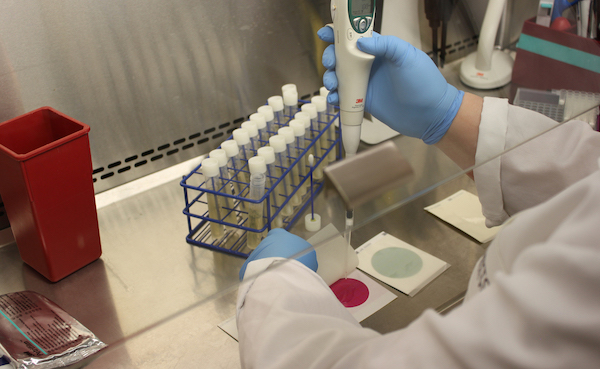

Adhering to the current FSMA (Food Safety Modernization Act), CGMPs (Current Good Manufacturing Practices) and HARPC (Hazard Analysis and Risk-Based Preventive Controls) procedures, our Total Quality System Technicians use a proactive approach to identifying and eliminating preventable food borne illness. We evaluate and select vendors based on these same FSMA, CGMPs and HARPC criteria, and we re-qualify existing vendors annually based on the consistent quality of their products, compliance with specifications and their ability to identify and reliably eliminate all potential food safety hazards before they enter our supply chain. This preemptive approach to quality assurance reliably eliminates preventable foodborne illness and enhances the quality of our products.

Our raw materials and manufactured products are inspected daily and must pass a battery of tests in our on-site physical chemistry and microbiology laboratories – all helping to ensure safe, consistent and wholesome foods. This, combined with our industry leading sanitation procedures and rigorous environmental testing protocols, makes Haliburton an industry leader in the Ready-to-Eat category.